Voron Trident 300 Build: Part 3

Posted on

Day 3! I've had some fun with ABS printing but have managed to get the A drive frame printed and mounted, as well as correcting half of a mistake.

The Y-axis extrusions now have a T-bar facing down. The orientation isn't called out in the LDO instructions. Instead, they rely on you finding the right place in the Voron manual for the T-nuts and correlating. This is really difficult to get right when you have no idea how the thing looks eventually, and when videos online don't even use these bars.

Spot the remaining mistake! Those front extrusions should have a T-bar facing the back, not the sides. I'll need to disassemble again.

DIY

This is a DIY project. If I wanted a printer right now, I'd buy an X1C or one of its cheaper clones. But most of those aren't open-source and are for a consumer who wants to get stuff done, rather than do donuts in the car park and compare notes.

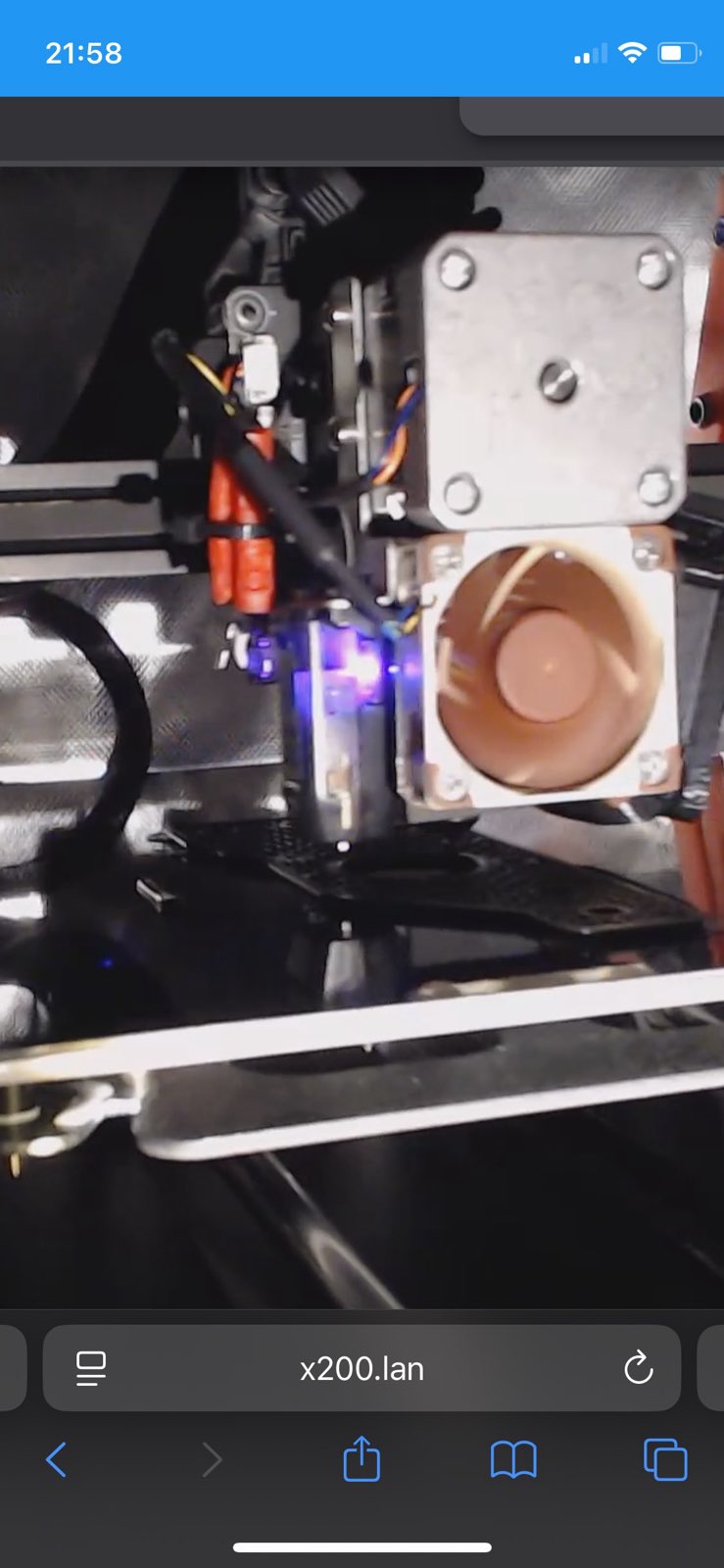

Part of my DIY disease is that I want everything to be done from scratch. That's the case with the printed parts. I got a huge kick from printing the casing for the motor and fitting it to the frame, despite several misprints, and the result being pretty ugly too:

I believe this will function correctly, though, as everything lines up as per the manual.

Here's a future part for the Stealthburner toolhead that was recommended as a test print:

Hotend upgrade

For the price of nearly half of a Print It Forward order I'm still avoiding, I decided to upgrade the hotend on the Ender V3 SE that I'm printing these parts on. I've been struggling with prints at 250°, not least because the default V3 SE hotend isn't designed for it. In fact, it'll give off nasty fumes beyond 240°. That hasn't arrived yet, but the wonders of modern logistics mean it'll be with me today.